Here are the Best Drill Press Upgrades You Can Make

Want to add storage, organization, versatility and dust collection to your drill press? In this post I'll walk you step-by-step through all the upgrades I just made to my benchtop drill press. I even added some hidden features that I think you'll want to try!

Materials & Supplies*

3/4" 4x8 Plywood

1/4" 4x8 Plywood (backs)

Misumi Aluminum Extrusion (for fence) - https://bit.ly/3LernlD

T-Track - https://amzn.to/3uu8mWH

Velcro Straps - https://amzn.to/3osh6bW

Set of Four Casters - https://amzn.to/3GxgpEp

Two Sided Tape - https://amzn.to/3gsJ0A4

1.25" Magnets - https://amzn.to/3J4QkOx

Contact Cement - https://amzn.to/34BMAVO

Centipede Work Holder - https://amzn.to/34iBHII

Set Up Blocks - https://amzn.to/3GsT8U3

Set of Forstner Bits - https://amzn.to/3B1Hezh

Laminate Roller - https://amzn.to/3rsbxfA

*I use affiliate links, please see details on my disclaimer.

Best Drill Press Upgrades - 4 Drawer Stand

To get started lets build from the ground up. That means building a stand that meets the following MUST goals: Have a small footprint, store ALL my drill bits and drilling accessories be mobile, and match the rest of my shop cabinets.

To do that I need to set up my Centipede work holder to help me break down some plywood.

This is my favorite way to break down plywood. I can cut it at a comfortable height and have access to all sides making it easy to cut with my track saw.

I’m going to make the stand out of ¾” plywood, except for a little bit of ¼” plywood for the drawer bottoms.

All I’m doing here is cutting this plywood into manageable chunks for the parts I need. I prefer to cut my parts to final dimension over at the table saw, so that’s where I’m headed next.

The first cut I make is to get rid of the rough factory edge. I want nice crisp edges on my parts.

Then I can cut my two side panels as well as the back and bottom panels.

I’m also going to cut all my drawer fronts out of one piece of plywood to achieve a continuous grain pattern for the front of the stand.

I then go ahead and cut all my drawer parts. I’m making four drawers in total.

After making the remaining cuts to get the stretchers and drawer accessory parts I have everything I need to start cutting joinery.

First I’m going to cut a rabbet along the back edge of each of the side pieces to fit the back panel.

To do this I’m going to use my set up blocks to set the height of the bade as well as the distance from the fence.

These little guys are so handy. Just grab and go!

After making the first cut in both sides I tap the fence slightly toward the blade and repeat the cuts.

I keep repeating this process until the blade just kisses the fence.

There you have it, two rabbets nice and clean.

The only other cuts I have to make are the groves in the bottom of the drawer parts to hold the drawer bottoms.

Once I dial in the perfect fit for the ¼” plywood I can run through all these parts in no time.

To assemble the drawers I’m going to use pocket screws. After cutting my pockets with my handy pocket hole station I can move on to getting these guys assembled.

Assembling the Drawers

Assembling these is really easy. I line up my parts in the right orientation with the front and back sitting between the two sides.

Notice how the groves are facing up and the back of the drawer sits below the grooves. That’s the key to making this so easy.

After I clamp up the sides making sure everything is flush I pop in my screws.

I then remove the clamps and check for square.

Finally, I can slide the bottom panel into the groves from the back side. This is why I cut the back panel short.

This is way easier than assembling the sides around the bottom all at once. And all I have to do is pop in a few brad nails and I’m done.

The other benefit to assembling the drawer upside down is that the sides are all flush on top, making for a nice smooth edge.

Assembling the Carcass

To assemble the stand I begin by attaching the bottom panel to the side using pocket screws. I have screws going in all different directions, including the front, which if you’re still awake and paying attention is a mistake.

I don’t need pocket holes along that edge #overpocketholed HA! Good thing this is the bottom of the stand.

Then I can do a dry fit of the back panel just to make sure everything lines up well before adding glue to the rabbets and clamping the back in place.

Pocket screws get added here to for extra strength since this stand will be holding a pretty heavy drill press on top.

The last things to add to the carcass are the stretchers so I flip the stand on it’s top. And slide the stretchers into place before clamping them in place.

Then I can rotate the carcass and attach them with pocket screws.

And with that the carcass is complete. I just need to wait for the glue to dry.

Once the glue is dry I can add these small blocks to the bottom to hold the casters.

I just screw them into place before screwing the casters to the blocks.

The drawer slides get installed on the drawers.

Then I installed in the stand using a spacer to make sure both sides are lined up perfectly at the top.

Then I cut the spacer down until it lines up with the location of my next set of slides.

I continue until I have all four sets of slides installed and I can slide my drawers into their new home.

To make the top of the stand I just fastened two pieces of ply together with screws and then trimmed the edges flush.

I cut some ¾” hard maple to serve as the edge banding, which will also match the other cabinets in my shop.

After gluing on the edge banding and waiting for it to dry, I attached it to the top of the stand with screws through the stretchers.

Making Drawer Fronts

For the drawer fronts I added iron on edge banding to give it a finished look.

This is a totally optional step for shop furniture in IMO, but if I’m going to look at this every day I want it to look clean and match the rest of the shop, so edge banding it is.

To drill for the drawer pulls I have this super handy jig from True Position that makes drilling repeated consistent holes fast and easy.

Installing Drawer Fronts

To install the drawer fronts my favorite trick is to use 2 sided tape to attach a scrap of ply to the bottom to act as a positive reference for aligning the first drawer front.

I can set my drawer front on the ledge I created and line it up for the boss level trick I’m about to show you.

To install the drawer front, drive two screws through the holes you made for the drawer pull.

This will fasten the front to the drawer temporarily while you screw the front in place from inside the cabinet.

The just pop those front screws out and drill all the way through the drawer.

Now just install your drawer pull hardware and boom, first drawer done.

And for my final trick, the trifecta of drawer front installation hacks I use a 1/8” strip of maple as a spacer to create a nice even gap between my drawer fronts.

Then I just work my way up the stand employing all my tricks until I get them all in and BAM this stand is complete!.

Well ALMOST complete. I still need some efficient storage solutions in these drawers.

Drill Press Stand Organization

The next upgrade I’m going to make for my drill press is to make it easy to organize these drawers. To start I’m going to install a couple of spacers in the top two drawers.

Next I take a small scrap of ¼” ply and glue some sides onto it using CA glue and activator.

The idea here is to make a quick and easy sliding tool tray to hold many of my loose drill bits.

I don’t think this is entirely needed, but I reinforce the tray with screws from the bottom.

Better to overengineer it and not need it than to skip this step and risk it falling apart with all my drill bits inside.

These trays will keep my loose bits or my most used items easily at hand while still allowing plenty of storage below for other items.

Forstner Bit Storage

The more I thought about storing my bits the more I kept wanting to eliminate steps. So I think I have a solution that will allow me to open the drawer, clearly see which bit I want, grab it and go. To begin, I cut a small scrap of ¾” plywood to fit inside one of the drawers.

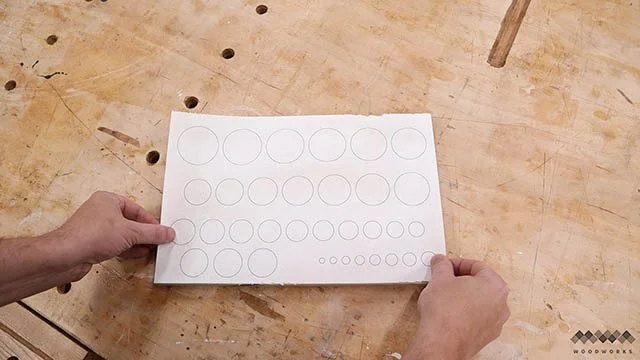

Next, I made a layout of all my forstner bits that I printed out on paper.

I attach the layout to the plywood and not I can use each bit to drill it’s own pocket.

That way every pocket is a perfect fit with the bit that goes there.

Once all the holes are drilled, I can remove the remainder of the template.

The final touch is to add the size of the drill bit next to each pocket for easy identification when looking down from above.

Then I could load up the bit holder and set it in it’s new home.

Drill Press Upgrades - Table and Fence

To create the drill press table I begin by cutting two pieces of ¾” ply and laminating them together with glue.

I get clamps on wherever I could reach and in the middle I use screws countersunk from the bottom to apply clamping pressure there.

I’ll go back and remove the screws later.

Once the glue is dry I take it to the jointer to make one edge flat to use as my reference edge.

Then back to the table saw where I put that edge against the fence and cut the opposite side parallel to it.

I then used my crosscut sled to trim and square up the other two sides.

Now is a good time to go ahead and label the front and back edge of the table as a reference for what comes next. I begin laying out various features like t track slots and clearance for the drill press post.

I want to know these locations because I want to add a row of magnets along the back to catch any stray bits that might wander off the edge. This will be a great hidden feature of this drill press table.

After marking the locations with a center punch, I used a forstner bit to drill the series of 1/8” deep pockets.

The magnets are held in place with CA glue.

Using Formica Laminate

Now that all the magnets are in place I am going to add a layer of black Formica to the top.

To do this I’m using contact cement.

Formica is a tough surface and will take a lot of wear and tear over time, not to mention adding really sweet look to this drill press table. If you’re wondering, you can buy 4x8 sheets of Formica at your local flooring store or anyone that sells counter top supplies. You can sometimes get lucky and find them at your big box home store.

After pressing the Formica onto the plywood, the bond is more or less permanent.

I can then use my trim router to flush up the Formica to the table.

How awesome does that look?

Adding T-Track and Cutting the Back Notch

OK, next I need to cut some dadoes in the top and bottom to accept some t-track.

Since my t-track will be the same distance from the edge on both sides I can make a cut, then flip my work piece around and make the second cut. Then I just nudge the fence away from the blade and make my next cut. This allows me to sneak up on the cut so the t-track fits perfectly with no slop.

I then repeated this same think on the bottom of the table. You’ll see why I’m doing this soon.

Next, I’m going to cut a notch out of the back of the table to accommodate the pillar of the drill press. This will allow for extra depth if I need to reposition the table to drill a hole in a hard to reach place.

I started this process using my jigsaw but quickly noticed the upward cut of the blade was chipping up the Formica pretty badly. To finish this I moved to the bandsaw which has downward cutting motion. This resulted in a much better experience and I had a lot more control over the finer cuts as well.

I finished up by sanding the curve to the reference lines.

Next, I trimmed off a small bit of the front corners with my track saw. I like this feature because it removes any sharp corners that you might bump into and this area of the table isn’t all that necessary for supporting a work piece.

After that I need to cut my t-track to length, so I mark my cut line and trim it at the miter saw. If you didn’t know, it’s perfectly fine to cut aluminum with woodworking tools. But a word of caution, if you’re the kind of person that forgets to put on your eye protection, definitely don’t skip that step when cutting aluminum. These little shards fly EVERYWHERE when you cut it and nothing will ruin your day faster than getting one of those in your eye.

With a self centering bit I drill the pilot holes. And screw the track in place.

Adding a Waste Plate

Now for the fun part, I need to create a recess to install a sacrificial plate.

To do that I cut a circle into a scrap of plywood and attach it with two sided tape.

I start by hogging out the majority of the material with a forstner bit. I needed to move to a hand drill for the last bit because my drill press couldn’t reach it.

To finish it off I’m using a flush trim bit in the router which will leave a flat bottom and smooth walls.

I then go back to the drill press to make a through hole.

This will allow me to pop out the sacrificial plate from underneath when it gets all chewed up.

For the sacrificial plates themselves I put a small chamfer on both sides. This will allow them to easily fall into recess in the table.

It also makes it easier to spin, which I’ll explain more about later.

One final touch is to chamfer all the edges and re-install the track.

Installing the Table

To install the new table I just add t-bolts to those tracks I added to the underside and then align those to the slots in the stock table of the drill press.

A couple fender washers and wing nuts will keep everything firmly in place.

Drill Press Table Fence

Then I can add the fence and this thing is ready to rock.

For the fence on this table I’m using this aluminum extrusion I ordered from Misumi.com I went with this because it considerably cheaper than buying stock aluminum fences from woodworking shops. This piece cost be just about 12 buck to buy.

It has slots for adding stops and accessories and it can be pretty low profile for a fence.

To make the fence work, I just need to drill holes for t-bolts.

I’m adding these holes on the wide face of the fence too so I can use the fence in both directions.

MAGNETS! NEAT!

And you can see here how those magnets on the back do a great job of holding stray drill bits and keeping them from rolling off the table.

I can also use the bottom tracks to store my stop blocks and hold downs.

Drill Press Upgrades Bit Caddy

To start making the tool caddy I draw some reference lines on a scrap of ¾” ply.

I then use the table saw to cut the main body free from the collar.

The bandsaw makes quick work of removing the waste.

And the belt sander smooths everything out.

Next I add through holes to the collar.

And a set of matching holes to the caddy.

I then drill two more hole which will be used to house these barrel bolts.

Now I can thread a furniture bolt into the barrel nut to test the alignment.

For the caddy itself I’m just going to drill a series of ¼”, 3/8” and ½” holes which will give me plenty of options for storing any of my bits on the caddy.

And on the far end of the caddy I bore some holes from the underside which I’ll use to add more magnets.

Now I can add a quick chamfer to all sides and install the caddy in it’s new home.

I’ve got room to hold several bits at once and I even drilled a through hole to hold my chuck key. The magnets I added are actually strong enough to hold a large plug cutting bit on its end.

Drill Press Dust Collection

To make the dust collection attachment I start with a small scrap of ply.

I find the center and then drill a through hole which will be used to hold a small length of dowel.

I just glue that into place.

After that I add a Velcro tie down and screw it into place using a panhead screw.

And then I bore a corresponding hole in the drill press table.

The dust collection attachment fits into the hole and the tie down wraps around the dust hose to hold it in place. If I need to adjust the position of the hose, I can loosen the strap and move the hose.

Let’s test this out by drilling some holes. Using the forstner bit it gets a good bit of the chips.

And when I use a twist bit it gets pretty much all the dust. Yep, I’d say this solution sucks!

So that wraps it up. Five upgrades added to my drill press to increase storage and organization as well as east of use and versatility.